Printing And Dyeing Wastewater Treatment Used Membrane Filter Press

Machine

Introduction

Filter press is a kind of mud treatment equipment developed for

solid liquid separation in industrial production. It is mainly used

in chemical, ceramic, petroleum, pharmaceutical, food, smelting and

other industries, as well as industrial filtration and sewage

slurry treatment. This equipment has the advantages of convenient

operation and maintenance and reliable operation. The mud cake

filtered by the filter press has a higher solid content and an

excellent separation effect.

Structural Advantages

Van filter plate

1. The filter plate is made of reinforced polypropylene, with

overall variable cross-section design, so that its flow resistance

is small, the flow rate is fast, and the filtering efficiency is

higher than that of the same filter plate;

2. Adopt special raw material formula and pressing process,

equipped with 4000 ton high pressure hydraulic press, and the

mechanical performance indexes of the filter plates are higher than

the relevant national standards;

3. The filter plate is made of TPE elastomer and alkali free glass

fiber polypropylene, which makes the filter plate have the

elasticity of rubber filter plate, and enhance the toughness and

rigidity of polypropylene filter plate. After being processed by

CNC machining center, the flatness of filter plate is less than 25

μ m, which makes the filter plate have good sealing performance

when it is pressed, and there is no spray or leakage when it is

fed.

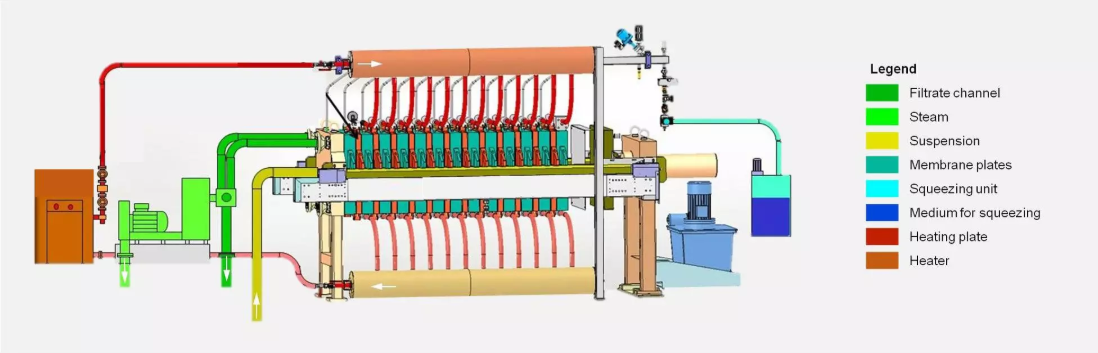

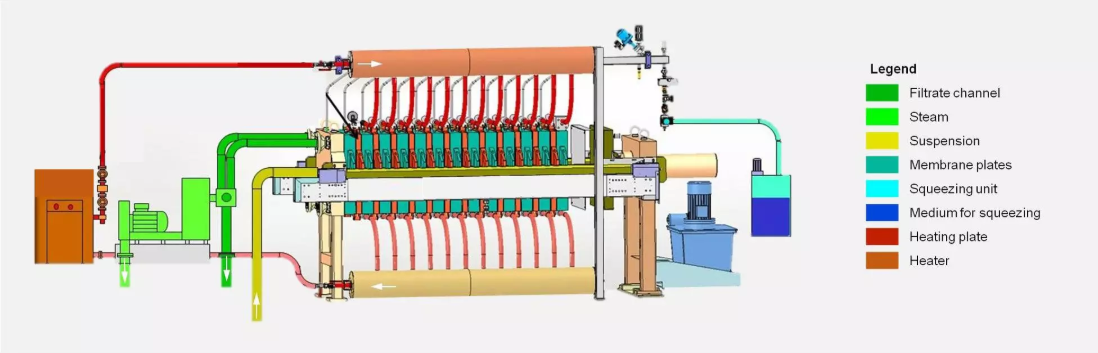

Working principle

LDHB filter press is extruded through the plate frame, so that the

water in the sludge is discharged through the filter cloth to

achieve the purpose of dehydration. In operation, under the

pressure of the feed pump, the liquid to be filtered is sent to

each filter chamber, and the solid and liquid are separated by a

filter medium (selecting a suitable filter cloth according to

different industries). The filter residue is formed on the filter

cloth until the filter chamber is filled to form a filter cake.

The filtrate passes through the filter cloth and flows along the

groove of the filter plate to the lower outlet hole passage, and is

discharged centrally. After the filtration is finished, the filter

press is opened to remove the filter cake (the filter cake is

stored between the adjacent two filter plates), and the filter

cloth is cleaned. Re-tighten the plate filter to start the next

working cycle. This continuously cycles through the work to achieve

the purpose of solid-liquid separation.

Model | Feed Material concentration (%) | Filter Area (m²) | Power (KW) | Capacity (t/h) | Weight (kg) | Overall Dimension (mm) |

| G50-80 | 20-40 | 50 | 15 | 0.80-1.60 | 3456 | 4110*1400*1230 |

| G80-80 | 20-40 | 80 | 15 | 1.32-2.60 | 4584 | 4990*1400*1230 |

| G100-100 | 20-40 | 100 | 24 | 1.70-4.00 | 6628 | 4900*1900*1600 |

| G150-125 | 20-40 | 150 | 27.5 | 2.50-5.00 | 9800 | 6010*2000*1600 |

| G200-125 | 20-40 | 200 | 35.5 | 3.00-7.00 | 12500 | 7050*2260*1600 |

| G250-125 | 20-40 | 250 | 44.5 | 4.00-8.00 | 14000 | 7890*2260*1600 |

| G300-125 | 20-40 | 300 | 52.5 | 5.00-7.00 | 25000 | 8800*2260*1925 |

| G400-150 | 20-40 | 400 | 62.5 | 6.00-10.00 | 30000 | 10670*2260*1925 |

| G500-150 | 20-40 | 500 | 82.5 | 8.00-12.00 | 36500 | 12650*2260*1925 |

Automatic cleaning device

The automatic cleaning device of filter cloth of filter press

mainly uses high-pressure water to wash the remaining materials in

the pore of filter cloth, so as to restore the permeability of

filter cloth and improve the filtering speed and service life of

filter cloth.

The filter cloth automatic cleaning device is highly automatic,

which reduces the labor intensity of manual cleaning of filter

cloth.

Application

Urban sewage sludge, tap water sludge, dredging sludge, industrial

sludge, industrial solid waste,Chlor alkali, inorganic salt, rayon

viscose, glycerin, silica, dye, pigment, silicic acid, sodium

sulfate,Manganese sulfate, iron hydroxide, titanium dioxide,

fluorine chemical industry, lithium chemical industry, silicon

carbide, nickel cobalt chemical industry,Non ferrous metals, metal

tailings, clean coal, tail coal, non-metallic ore

Wine, rice wine, alcohol, edible oil, citric acid, fruit juice

pectin, soy sauce, syrup,All kinds of starch, concentrated soup,

seaweed gum, beer wort, palm oil, beet sugar,

sucrose,Pharmaceutical intermediates, APIs, Chinese patent

medicines, fermentation broth, enzyme preparations

Packing and Delivery

1. The normal package is plastic cloth for main machine and wooden

for parts.The wooden box will be fumigated, can also pack it

according to customers special request.

2. The normal package is plastic cloth for main machine and wooden

for parts.The wooden box will be fumigated, can also pack it

according to customers special request.