Benenv Co., Ltd

Jiangsu Benenv Environmental Technologies Co., Ltd. Has always

been adhering to the fate of continuously creating values for

customers, and is committed of becoming a World-Class solution

provider for waste treatment and recycling. Benenv provide design,

engineering, supply and installation of environmental projects. The

company possesses complete sets of process design, equipment

supply, constructions, and technology innovation. We have various

experiences in wastewater treatment, industrial & domestic. After

years of research, development and testing, Benenv Environmental

has developed the elliptical Wave Separator & the Multi Disk Screw

Press for sludge dewatering, The super sludge dryer, The sludge

carbonization furnace, The high temperature vertical fermentation

tank, and the mobile treatment types with independent intellectual

property rights. A series of overall solutions for the waste

treatment are protected, currently with 12 invention patents and

more than 30 utility model patents.

Products Shared in more than 60 Countries

At present, our products have exclusive agents in France, the

United States, Canada, Poland, Malaysia, Indonesia, the Middle

East, India, etc., has more than 4500 installations in more than 60

countries, and has become the sludge dewatering benchmark in Asia.

We have international certificates such as ISO9001:2015, CE

certificate.

Business Model

Japanese Technology + Made in China (Lower cost advantage) +

Professional Overseas sales network

Benenv Co. Ltd. is an Original Equipment Manufacturer for many

international companies. We share our technologies in more than 60

countries such like France, USA, Canada, Poland, Belgium, Malaysia,

Indonesia, Middle East, Africa, India, Vietnam, Latin America ….

Sludge Dewatering Machine Equipment, Screw Type Sludge Dewatering

Press Sludge Screw Press, Dewatering Sludge Machine Screw Press

,Sewage Treatment Equipment ,Sluge Treatment Plant,Screw Press

Sludge Dewatering ,Dewatering Sludge,Dewatering Machine For Sludge,

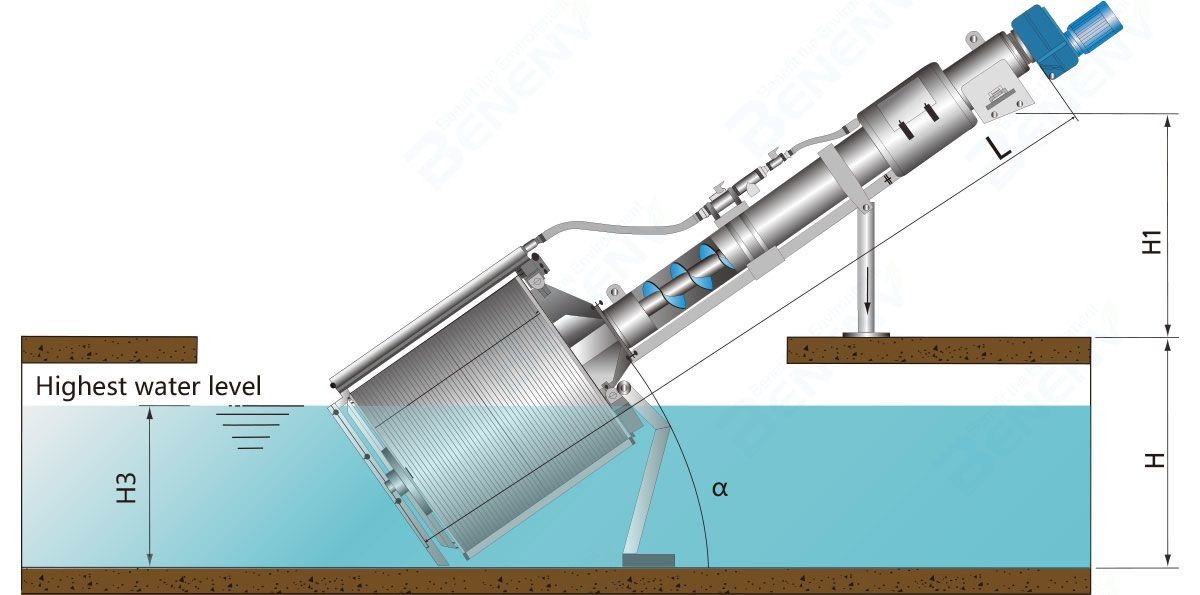

Dewatering Sludge Machine Screw Press, Rotary Drum Bar Screens,

Equipment Daf, Daf Price ,Dissolved Air Flotation System Price,

Sludge Shaftless Screw Conveyor,Chemical Dosing Device ,Mbbr

Price,Mbbr Media,Disc Diffuser, Polymer Preparation Chemical Dosing

System